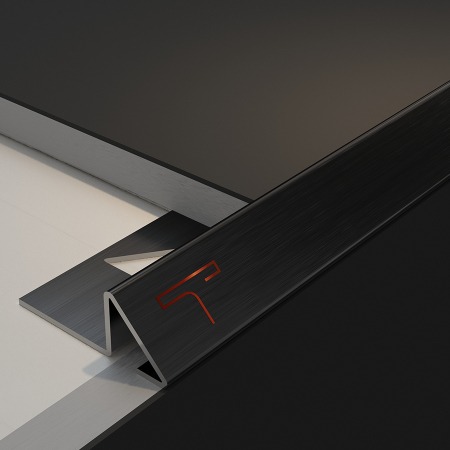

In the realm of metallurgy, understanding Transition Profiles, particularly in stainless steel (SS), holds paramount importance. This article delves into the intricate details of SS transition profile, shedding light on their significance, types, applications, and more.

Define the Topic

Transition profiles in stainless steel refer to the changes in material properties across different temperature ranges. These transitions profoundly influence the mechanical, chemical, and physical characteristics of stainless steel.

Relevance and Importance

The study of transition profiles is crucial for engineers, manufacturers, and designers involved in the production and application of stainless steel. It aids in optimizing material selection, ensuring product performance, and enhancing durability.

Types and Categories

Transition profiles in stainless steel can be categorized based on various factors such as alloy composition, heat treatment, and environmental conditions.

Alloy Composition

- Ferritic Stainless Steel: Exhibits a transition profile characterized by changes in magnetic properties with temperature variations.

- Austenitic Stainless Steel: Known for its stable austenitic phase at room temperature, offering superior corrosion resistance.

Heat Treatment

- Quenching and Tempering: Heat treatment processes that influence the transition profile by altering the microstructure of stainless steel.

Environmental Conditions

- High-Temperature Transitions: Changes in mechanical properties observed at elevated temperatures, impacting the material’s performance in industrial applications.

Symptoms and Signs

Identifying the transition profile in stainless steel involves recognizing the symptoms and signs indicative of material behavior under different conditions.

Magnetic Changes

- Magnetic Susceptibility: Variations in magnetic properties, such as paramagnetism or ferromagnetism, signify transitions in stainless steel.

Mechanical Properties

- Strength and Ductility: Shifts in mechanical behavior, including changes in tensile strength, hardness, and elongation, indicate transitions within the material.

Causes and Risk Factors

Several factors contribute to the emergence of distinct transition profiles in stainless steel, ranging from alloy composition to external stimuli.

Alloy Composition

- Elemental Composition: The presence of alloying elements like chromium, nickel, and molybdenum influences the material’s transition behavior.

Temperature Fluctuations

- Thermal Exposure: Exposure to varying temperatures during manufacturing, processing, or service conditions can trigger changes in the transition profile.

Diagnosis and Tests

Accurately diagnosing the transition profile of stainless steel involves employing specialized tests and analytical techniques.

Differential Scanning Calorimetry (DSC)

- Principle: Measures the heat flow associated with phase transitions in stainless steel, providing insights into its thermal behavior.

X-Ray Diffraction (XRD)

- Analysis: Determines the crystalline structure of stainless steel, aiding in identifying phase transformations across temperature ranges.

Treatment Options

Managing transition profiles in stainless steel necessitates employing appropriate treatments and interventions to optimize material performance.

Heat Treatment

- Annealing: Restores the material’s microstructure and alleviates stress-induced transitions, enhancing its mechanical properties.

Surface Modification

- Passivation: Forms a protective oxide layer on the surface of stainless steel, mitigating corrosion-induced transitions.

Preventive Measures

Implementing preventive strategies is vital for minimizing the adverse effects of transition profiles and ensuring the longevity of stainless steel components.

Material Selection

- Alloy Design: Choosing stainless steel grades with stable transition profiles suitable for specific applications minimizes the risk of unexpected material behavior.

Environmental Control

- Temperature Regulation: Maintaining consistent environmental conditions reduces the likelihood of abrupt transitions in stainless steel.

Personal Stories or Case Studies

Real-life experiences underscore the practical implications of transition profiles in stainless steel, highlighting the importance of understanding and managing these phenomena.

Case Study: Aerospace Industry

- Scenario: A manufacturer of aerospace components encountered unexpected failures due to transition-induced embrittlement in stainless steel fasteners.

- Outcome: Through meticulous analysis and material optimization, the transition profile was tailored to meet the stringent performance requirements of aerospace applications.

Expert Insights

Gaining insights from industry experts elucidates the nuances of transition profiles in stainless steel and offers valuable recommendations for effective management.

Expert Opinion: Dr. Sarah Anderson, Materials Engineer

“Understanding the transition profile of stainless steel is imperative for ensuring structural integrity and reliability in critical applications. By leveraging advanced characterization techniques, we can tailor the material’s properties to meet specific performance criteria.”

In conclusion, transition profiles play a pivotal role in shaping the behavior and performance of stainless steel across diverse applications. By comprehensively understanding these profiles and implementing appropriate measures, stakeholders can optimize material selection, enhance product reliability, and mitigate potential risks.