Small and Medium-sized Enterprises (SMEs) form the backbone of economies worldwide, contributing to innovation, job creation, and economic growth. In their pursuit of efficiency and competitiveness, SMEs are increasingly turning to advanced technologies. Collaborative robot welding, or cobot welding, has emerged as a transformative solution for SMEs, offering a cost-effective and flexible approach to welding processes. This article delves into the specific advantages and considerations of implementing collaborative robot welding in the context of SMEs.

Tailored Solutions for SMEs:

1. **Affordability:**

SMEs often operate within constrained budgets, and the initial investment in robotic automation can be a significant consideration. Collaborative robot welding provides a cost-effective entry point into automation for SMEs, offering a balance between affordability and advanced technology.

2. **Flexibility and Adaptability:**

One of the key challenges faced by SMEs is the need to adapt quickly to changing market demands. Collaborative robots are inherently flexible and can be easily reprogrammed for different welding tasks. This adaptability allows SMEs to respond swiftly to shifts in production requirements without incurring significant downtime.

3. **Ease of Integration:**

Collaborative robot welding systems are designed with user-friendly interfaces, making them accessible to operators with varying levels of technical expertise. The ease of integration minimizes the learning curve for SMEs, enabling a smooth transition into automated welding processes.

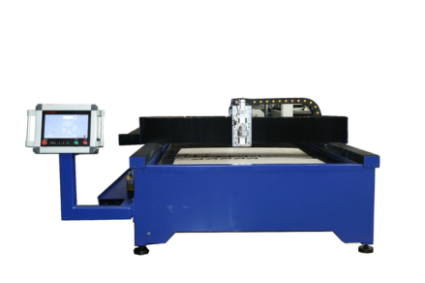

4. **Space Efficiency:**

SMEs often operate in limited physical spaces, and traditional industrial robots may be impractical due to their size and footprint. Collaborative robots, designed to work alongside human operators, are generally compact and space-efficient. This makes them suitable for SMEs with spatial constraints, allowing for efficient utilization of available workspace.

Operational Advantages for SMEs:

1. **Improved Productivity:**

The integration of collaborative robot welding systems significantly enhances productivity within SMEs. Cobots work tirelessly, providing continuous and consistent performance. This increased efficiency allows SMEs to meet production targets more effectively without compromising on quality.

2. **Enhanced Quality and Consistency:**

Quality control is paramount for SMEs aiming to build a strong reputation in the market. Collaborative robot welding ensures precise and consistent welds, reducing variations and defects. This focus on quality enhances the overall product reliability for SMEs.

3. **Workforce Empowerment:**

Rather than replacing human workers, collaborative robot welding empowers the existing workforce. SMEs can utilize cobots to handle repetitive and physically demanding welding tasks, freeing up skilled workers to focus on more intricate aspects of the manufacturing process, such as quality control and decision-making.

4. **Safety Measures:**

Safety is a top priority for SMEs, and collaborative robots are designed with built-in safety features. Advanced sensors and programming enable cobots to work in close proximity to human operators safely. This ensures a secure working environment, minimizing the risk of workplace accidents.

Challenges and Considerations:

While collaborative robot welding holds immense promise for SMEs, there are considerations that need to be addressed. SMEs must assess factors such as the specific welding requirements, the learning curve for operators, and the ongoing maintenance costs to ensure a successful implementation.

Conclusion:

Collaborative robot welding presents SMEs with a transformative opportunity to embrace automation and enhance their competitiveness in the market. The tailored solutions, affordability, and operational advantages make cobot welding an attractive option for SMEs seeking to optimize their welding processes. As technological advancements continue to drive innovation, the integration of collaborative robots in welding operations stands as a testament to the resilience and adaptability of SMEs in the ever-evolving landscape of manufacturing. Check out Cyber Weld for more